High Temp Shrink Sleeves

|

| An installed WPC100M sleeve. |

In the oil and gas coatings world, many lines are designed to have the capability to coat a pipeline that could operate at up to 100C. In terms of factory coatings, a 100C line has a number of options: high temp FBE, PP or PE being just a few of them. WPC100M is compatible with any of those options. The aggressive mastic of the WPC100M bonds well to any commonly applied pipeline coating. In addition, the surface preparation is not nearly as stringent as many epoxies and WPC100M is a very practical field application. Save money on surface prep and save time on labor with WPC100M.

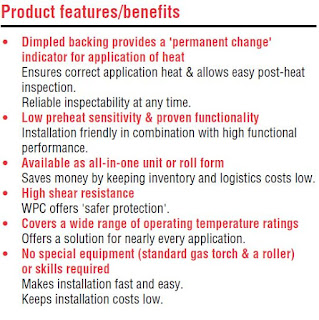

WPC100M Features and Benefits:

- Dimpled backing provides a 'permanent change' indicator for application of heat. This ensures correct application of heat and allows easy post heat inspection. Reliable inspectability at any time; even hours, days, weeks or months later.

- Low preheat sensitivity and proven functionality. Installation friendly in combination with high functional performance.

- Available as all in one unit or roll form - saves money by keeping inventory and logistics costs low.

- High shear resistance - WPC offers safer protection.

- Covers a wide range of operating temperature ratings. Offers a solution for nearly every pipeline coating application.

- No special equipment or skills required - only a standard gas torch and a roller. Fast, easy and low cost application.

- WPC100M rated to 80C onshore / 100C offshore

- Compatible with PE, PP, FBE, Tape and Coal Tar

- 100C preheat temperature required

- ST 2 1/2 - ST3 or SA 2 1/2 surface prep required

- Soil Stress Restrictions: NONE

No comments:

Post a Comment