Raychem / Covalence DIRAX

Installed On Cured Protal 7200

Materials and Equipment Required:

·

Appropriate sized DIRAX kit

·

Approved adjustable Propane Torches w/ regulator

·

Temperature measuring equipment (contact

pyrometer)

· Standard

safety equipment

·

Heat resistant gloves

·

Silicone roller

Lightly abrade Protal

7200 and ARO coating adjacent to field joint, then use a solvent to remove all

oil, grease, mud and dust from the area where the DIRAX will be installed.

Mix the S1301M Epoxy

Primer. Pour smaller can into larger

can. Mix for approximately 1

minute. If working in cooler weather,

keeping epoxy inside of a truck (at a slightly warmer temperature) can make the

epoxy easier to mix.

Using a propane torch

with a broad, bushy, yellow flame, gently preheat Protal 7200 and adjacent ARO

where the DIRAX will be installed to a temperature in the 160F range

(minimum: 140F; maximum: 180F). The purpose of this preheat is to most

efficiently use the S1301M epoxy primer, minimizing wastage. Check preheat temperature with a contact

pyrometer.

Use the supplied

applicator pad to apply the mixed epoxy primer over the entire surface to be

covered (Protal 7200 and ARO).

Note: When installing 12” wide

sleeves on a 12” OD pipe – each individual epoxy kit contains enough epoxy to

coat 3 field joints.

Immediately after

application of the S1301M epoxy primer, and while the primer is STILL WET,

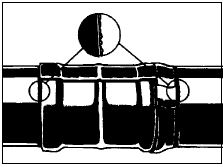

loosely wrap the DIRAX sleeve centrally around the girth weld. Wrap the sleeve (adhesive side down) around

the area to be coated. Make sure the

DIRAX sleeve wraps around the pipe and overlaps itself by at least 2

inches.

Gently preheat the

inside layer of the adhesive layer just next to the closure strip for 2 seconds

and press it down on the sleeve end on the pipe to form a tube (making it stick

to the other end of the sleeve).

Using the approved

torch, with a broad, bushy, yellow flame, start heating the closure area. As you see the closure begin to ‘soften’ pat

it down firmly with a gloved hand.

Continue heating and patting every few inches until the whole patch area

is finished. As the closure is properly

heated, you should see a light cross hatch texture appearing in the

closure.

Start heating (with a

broad, bushy, yellow flame) the sleeve at the side of the leading edge (the

side toward where the bore hole is).

Move the torch continuously CIRCUMFERENTIALLY (up and down) in a paint

brush motion all the way around the sleeve.

Work (moving torch up and down) from one end of sleeve; toward middle –

then toward other end of sleeve – always UP AND DOWN with yellow flame

contacting the sleeve.

Upon completion of

“shrink”, while the DIRAX is still hot and soft, run a small hand roller over

the overlap area (where one layer of sleeve overlaps onto the other layer of

sleeve, to push out any potential trapped air.

Pay particular attention to the weld and cutback area. Reheat any area if necessary. At this stage is when the temperature reading

can be taken on the backing of the sleeve with a contact pyrometer. Sleeve backing temperature is not to exceed

350F which can be easily achieved with installer taking care and working with

Torch at proper output levels (but must exceed 267F or the sleeve will not

shrink).

Main DIRAX sleeve is

complete when: sleeve has fully

conformed to the pipe / Protal and adjacent ARO; there are no cold spots or

dimples in the sleeve surface; there are no major blisters on the sleeve

surface, adhesive flow is evident on both edges after sleeve is cool.

It is now time to

install 3” wide leader strip on the side of the sleeve that will go into bore

hole first. That area should still be at

least 160F (but if not; it will be necessary to re-pre-heat).

Wrap the leading edge

/ wear cone over the transition between the DIRAX and the ARO. Make sure the closure for the wear cone is

placed away from the main sleeve closure.

Install this wear cone the same way as the DIRAX sleeve – wrapping

around pipe to overlap onto self; securing the closure and then shrinking the

wear cone with a broad, bushy, yellow flame.

Smooth down any edges

of the sleeve with the silicone roller.

Sleeve is fully recovered when: it is fully conformed to pipe surface /

Protal / Denso. There are no cold spots;

dimples. Profiles are visible beneath

sleeve. Adhesive flow evident on all

edges after sleeve has cooled. Sleeve

must be cooled to ambient temperature (and epoxy cured) before it should see

soil stresses.

No comments:

Post a Comment