Perp Melt Sticks - Easy Repair for PE Pipe Coating

|

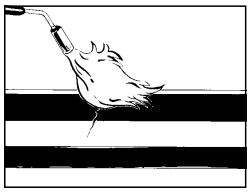

| A Perp Melt Stick in Action |

Perp Melt Sticks are heat sensitive, polyethylene copolymer sticks used for small superficial damage to PE coatings where the damage does not extend to the bare metal. Generally speaking, installation of Perp Melt Sticks is done with a standard gas torch. After eliminating all sharp edges, cleaning and preheating, the Perp Melt Stick is heated above the damaged area until becoming glossy (beginning to melt). The flowing adhesive is then spread onto the scratches, forming a tight bond with the PE substrate. After it cools down, the hardening, cooling adhesive is smoothed flush with the PE line coating using a paint scraper of some kind.

Perp Melt Sticks are high economical and versatile. The adhesive also shows resistance to high shear forces and excellent adhesion to commercial PE mill applied coatings. They can be used on pipelines operating at up to 80C (176F).

1. Remove loose coating from the damaged area with a knife, scraper or wire brush. Eliminate all sharp edges and clean the damaged area and adjacent coating to remove all foreign materials such as dirt, rust, oil, grease and moisture.

2. Preheat the pipe coating to 60C.

3. Heat the end of the Perp Melt Stick until it becomes glossy.

4. Spread the molten adhesive onto the damaged area.

5. When the PE is hard, smooth the molten adhesive flush with the PE line coating by use of a point scraper.

No comments:

Post a Comment