Repairing Damage to a Shrink Sleeve

|

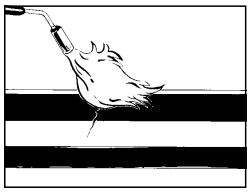

| A shrink sleeve during installation process |

So first things first, it is incredibly rare in my experience that a shrink sleeve is damaged. In my 24 years being heavily involved with shrink sleeve sales, specifications, training and product recommendations I've sold more than a million shrink sleeves (so a million field joints coated). Here are the reasons I've been told that damage occurred (spoiler alert: there aren't many):

- A truck backed into the pipe and struck the field joint; tearing the sleeve.

- An installer was checking his phone while the torch (with no regulator) burned a hole clean through the sleeve.

- A disgruntled worker vandalized some sleeves that had been installed the previous day.

- The installer tried to install using a rosebud torch instead of a propane torch (with a regulator set to provide a large, bushy, yellow flame).

- A backhoe accidentally brushed against the shrink sleeve.

- The installer didn't think the sleeve was the right size, so he trimmed it down himself resulting in there being no sleeve overlap onto itself -- and the sleeve not being wide enough to overlap onto the adjacent factory applied coating by the required 2-3 inch minimum.

That's it. As you may notice, every one of those reasons can be classified as an installation error. The Covalence plant in Mexico does an incredible job making sure that every roll of sleeve material that they ship has been inspected and passed all QA/QC requirements. They have been doing this a very long time and they are GOOD at it. The simple fact is: sleeves are very rarely damaged.

BUT -- if you do have a damaged sleeve - see below for the bare basics....BUT -- I think it would be better if you gave me a call and we can discuss it (936/321-3333). It can also be helpful if you send me a photo of the damaged area in advance, so we can be certain we are both on the same page (photos can be emailed to: steve@jsicoatings.com).

SIGNIFICANT DAMAGE

For the sake of this ridiculously brief overview; I'm considering "significant damage" to be any damaged area larger than a 3" square. This could be a 'gash' in the sleeve backing; or this could be a scrape through the sleeve exposing bare steel. In many cases, the simplest solution for repair would be to completely strip off the damaged sleeve; re-clean the pipe and re-apply a brand new sleeve.

You can't go wrong doing that anytime, except, heat shrink sleeves are not designed to be easily removed from the pipe. They are designed to stick to that pipe for the life of the line.

Because of that, I recommend instead that you trim off any damaged PE that you can safely trim off. Then you fill the 'void' left in that coating with a Perp Filler material (a butyl mastic filler called S-1137 that is 2" wide, 10 feet long and a few mils thick - much like a putty; the mastic can be shaped and pressed into the void bringing a contiguous surface to the remaining portion of the damaged sleeve.

From there, a new sleeve (preferably wider than the first) can be installed, adding a second layer to the good coating and completely encapsulating and isolating the originally damaged area. Problem solved.

MODERATE DAMAGE

I would consider "moderate damage" to cover anything from an area less than 3" x 3" and anything greater than a pinhole sized area of damage. In that case, you would use the S1137 Perp Filler (just like we did for significant damage) and we would rebuild that damaged area. We would then use a PERP (stands for Poly-Ethylene Repair Patch). PERP is sold in rolls and "patches" are cut from that roll. PERP doesn't shrink like other sleeves do, so you cut a patch that is at least 3 inches larger in every direction than the damaged area. That patch is heated, patted down and rolled. Once it cools it will be very well bonded to the underlying sleeve -- and your damaged area has been rebuilt, encapsulated and repaired.

MINOR DAMAGE

Minor damage is what I would consider a pinhole. Maybe someone poked the sleeve with a nail or welding rod while the sleeve was very hot and molten. In that case, you would use a product called a Perp Melt Stick. Perp Melt Sticks are cylinders of pure adhesive (think of it as being a bit similar to a candle). With a torch, the Perp Melt Stick is heated -- and as that adhesive flows, you direct it into filling and sealing the pinhole.

So there you have it -- an incredibly overly simplified explanation of your heat shrink sleeve repairing options. I can't stress enough: if you have a problem: CALL ME!