Powercrete J Thickness Test

|

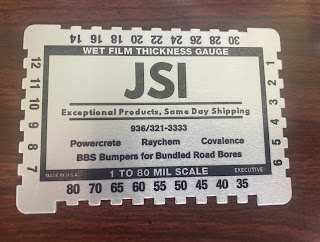

| This tool is critical when installing Powercrete |

Just about every specification for a pipeline coating out there in the world today is going to also supply the contractor with a coating thickness requirement. In my experience, that often ranges anywhere from 20 mils to 60 mils (there are plenty of exceptions with most falling at 30-40 mils in my experience).

Why does the coating thickness matter? Well, pipeline engineers are designed pipelines (including the coatings) with certain parameters in place around their project. What is the soil like? What is the backfill going to be? What sort of abrasion and other forces are they expecting to see within a bore?

In addition, of course the coating thickness is a factor when considering things like the Tabor Abrasion tests. The thicker the coating (within reason) the more abrasion a coating can withstand. Thickness is IMPORTANT and all too often, the top of the pipe and the bottom of the pipe come up short.

That is why crews in the field need a wet film thickness gauge as the first line of defense to help installers ascertain how their efforts to build thickness are going. It is easy to get distracted out there -- you need a quick and easy way to see how thick your coating is during the installation process.

And if you have a crew who is just going to put the epoxy on as thick as they possibly can (material costs be damned) then keep this in mind: many coatings have a MAXIMUM thickness. When you exceed a coatings maximum thickness, you run the risk of introducing cracks in the coating.

So there you have it --- if you'd like one of these JSI wet film gauges, shoot me an email at steve@jsicoatings.com and I will mail one out to you!

No comments:

Post a Comment