Question: What are the advantages of using a wrap around shrink sleeve versus using a tubular shrink sleeve?

Answer: First of all, if tubular sleeves are a readily available option, then we must be talking about a pipeline that will operate at ambient temperatures. We are able to offer higher temperature tubular sleeves; but it is an extremely rare occurance.

Second, if tubes are a readily available option, we must be talking about a pipeline ranging from 2" to 10". Tubes just aren't typically used on pipelines larger than 10". Now, in my world; when we talk about sleeves for an ambient temperature pipeline; we are talking about WPCT (as the wrap around) and TPS (as the tubular product).

WPCT style sleeves are often called "wrap around"; "shrink wraps"; "cigarette wraps" or "zipper sleeves". They are (obviously) wrapped around the field joint AFTER the weld has been made (and after the weld area has cooled down below 250F).

TPS style sleeves are often called "tubular sleeves"; "shrink tubes"; "sock type sleeves" or "slip on shrink sleeves". They must be slipped onto the pipeline before the weld has been made (and really before the pipe has even been butted together). The TPS shrink sleeve is then moved down the pipe so that it is far enough away from the weld to avoid weld spatter or excessive heat. Once the weld has been completed and the pipe has cooled to below 250F; the TPS sleeve is slid back into place; centered over the weld and then the release paper is removed. It is important to note that once the release paper is removed, it will be VERY difficult to relocate the TPS sleeve as it will be solidly stuck in place (the mastic is very aggressive).

When considering the actual material make up (the actual components that make up the backing and the adhesive); WPCT heat shrink sleeves and TPS shrink sleeves are virtually identical. Both uses an identical backing (though the TPS does have a slightly higher shrink ratio). Both also utilize the same, aggressive, proven mastic sealant.

All of that to say; technically there is very little (if any) difference. The TPS shrink sleeve must be slipped onto the pipe prior to welding (which does require some planning). The WPCT sleeve does require the additional step of securing the closure (one extra step). Otherwise; it is purely up to the end user. Some prefer wraps; some prefer tubes.

Answer: First of all, if tubular sleeves are a readily available option, then we must be talking about a pipeline that will operate at ambient temperatures. We are able to offer higher temperature tubular sleeves; but it is an extremely rare occurance.

Second, if tubes are a readily available option, we must be talking about a pipeline ranging from 2" to 10". Tubes just aren't typically used on pipelines larger than 10". Now, in my world; when we talk about sleeves for an ambient temperature pipeline; we are talking about WPCT (as the wrap around) and TPS (as the tubular product).

|

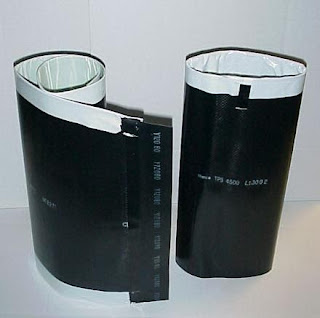

| WPCT wrap around shrink sleeve on the left; TPS tubular shrink sleeve on the right |

TPS style sleeves are often called "tubular sleeves"; "shrink tubes"; "sock type sleeves" or "slip on shrink sleeves". They must be slipped onto the pipeline before the weld has been made (and really before the pipe has even been butted together). The TPS shrink sleeve is then moved down the pipe so that it is far enough away from the weld to avoid weld spatter or excessive heat. Once the weld has been completed and the pipe has cooled to below 250F; the TPS sleeve is slid back into place; centered over the weld and then the release paper is removed. It is important to note that once the release paper is removed, it will be VERY difficult to relocate the TPS sleeve as it will be solidly stuck in place (the mastic is very aggressive).

When considering the actual material make up (the actual components that make up the backing and the adhesive); WPCT heat shrink sleeves and TPS shrink sleeves are virtually identical. Both uses an identical backing (though the TPS does have a slightly higher shrink ratio). Both also utilize the same, aggressive, proven mastic sealant.

All of that to say; technically there is very little (if any) difference. The TPS shrink sleeve must be slipped onto the pipe prior to welding (which does require some planning). The WPCT sleeve does require the additional step of securing the closure (one extra step). Otherwise; it is purely up to the end user. Some prefer wraps; some prefer tubes.

No comments:

Post a Comment