Question: Is it acceptable to use HTLP60 shrink sleeves without using the epoxy?

Answer: Unfortunately, no. The adhesive of the HTLP60 sleeve is specifically designed to require the epoxy to act as the bonding agent between the sleeve adhesive and the bare steel of the pipeline. Without the epoxy, the adhesive will not achieve the desired bond strength.

For some people this can be confusing. Once upon a time (15 years go) there was a product called WPC60 which was VERY similar to the HTLP60 sleeve system; but didn't require any epoxy to be used. It was a great product, it just wasn't used very often. As a result; WPC60 was obsoleted way back when and in its place we recommend using the HTLP60 sleeve system.

Don't worry though. The S1301M epoxy is VERY easy to work with. It is installed in a very thin layer and does not require the 'work' that stand alone epoxies require of your crew. The strength and dependability of the coating system is also less reliant on installer skill as between the epoxy; the preheating and the shrink sleeve there are a number of systems in place to be sure even the most un-skilled laborers are able to properly and consistently install the HTLP60 sleeve system.

If you're interested in seeing it for yourself, give us a call and we can arrange a demonstration right here at our facility!

Answer: Unfortunately, no. The adhesive of the HTLP60 sleeve is specifically designed to require the epoxy to act as the bonding agent between the sleeve adhesive and the bare steel of the pipeline. Without the epoxy, the adhesive will not achieve the desired bond strength.

For some people this can be confusing. Once upon a time (15 years go) there was a product called WPC60 which was VERY similar to the HTLP60 sleeve system; but didn't require any epoxy to be used. It was a great product, it just wasn't used very often. As a result; WPC60 was obsoleted way back when and in its place we recommend using the HTLP60 sleeve system.

|

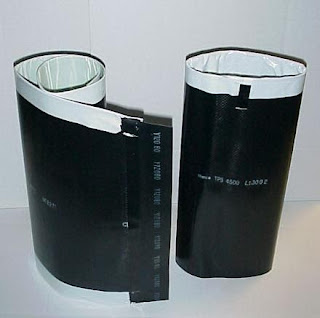

| S-1301M Epoxy is used with HTLP60, DIRAX and other products. |

If you're interested in seeing it for yourself, give us a call and we can arrange a demonstration right here at our facility!